Working in confined spaces poses unique challenges and hazards that are not present in open environments. One of the most critical risks is the presence of hazardous gases, which can lead to asphyxiation, poisoning, or explosions. Confined space gas detectors are essential tools designed to detect and monitor gas levels, ensuring the safety of personnel.

In this comprehensive guide, we’ll explore these devices, how they work, and why they’re indispensable in various industries.

What Is a Confined Space?

A confined space is an area that:

- Is large enough for a worker to enter and perform tasks

- Has limited or restricted means of entry or exit

- Is not designed for continuous occupancy

Common examples include storage tanks, silos, sewers, and underground utility vaults.

Why Are Confined Spaces Hazardous?

Confined spaces can accumulate toxic gases, have low oxygen levels, or contain combustible atmospheres. The lack of natural ventilation exacerbates these risks, making gas detection a critical safety measure.

The Importance of Gas Detection in Confined Spaces

Confined spaces present unique safety challenges due to their limited entry and exit points, restricted airflow, and potential for hazardous atmospheres. Gas detection is crucial in these environments to protect workers from unseen dangers that can lead to serious injuries or fatalities.

Potential Hazards

Oxygen Deficiency or Enrichment

- Oxygen Deficiency: Normal air contains approximately 20.9% oxygen. Levels below 19.5% are considered oxygen-deficient and can cause symptoms like dizziness, impaired judgment, unconsciousness, and even death due to asphyxiation.

- Oxygen Enrichment: Oxygen levels above 23.5% increase the risk of fires and explosions, as materials can ignite more easily and burn more intensely.

Toxic Gases

- Hydrogen Sulfide (H₂S): A colorless gas with a rotten egg smell at low concentrations but becomes odorless at higher, dangerous levels due to olfactory fatigue. It can cause respiratory irritation, unconsciousness, and death.

- Carbon Monoxide (CO): An odorless, colorless gas that interferes with the blood’s ability to carry oxygen. Symptoms of CO poisoning include headaches, dizziness, weakness, and in high concentrations, it can be fatal.

Flammable Gases

- Methane (CH₄): Odorless and highly flammable, methane can create explosive atmospheres when mixed with air in certain proportions. A small spark in a methane-rich environment can lead to explosions.

Regulatory Compliance

Occupational Safety and Health Administration (OSHA)

- Mandates Gas Monitoring: OSHA requires employers to evaluate confined spaces for potential hazards, including atmospheric dangers, before entry.

- Standard 29 CFR 1910.146: Specifies the need for atmospheric testing for oxygen content, flammable gases and vapors, and potential toxic air contaminants.

- Permit-Required Confined Spaces: Spaces that have or may have hazardous atmospheres require a permit system to control entry, ensuring that proper precautions and gas monitoring are in place.

Why Compliance Matters

- Legal Responsibility: Failure to comply with OSHA regulations can result in fines, legal action, and increased liability.

- Worker Safety: Adhering to regulations helps prevent accidents, injuries, and fatalities by ensuring that hazards are identified and controlled.

- Operational Efficiency: Safe working conditions reduce the likelihood of incidents that can cause downtime and disrupt operations.

What Is a Confined Space Gas Detector?

A confined space gas detector is a specialized device designed to detect and monitor hazardous gases within confined spaces. These areas are characterized by limited entry and exit points, and inadequate ventilation, and are not intended for continuous occupancy. The unique conditions of confined spaces can lead to the accumulation of dangerous gases, making gas detection essential for worker safety.

Purpose and Function

Safety Monitoring

The primary purpose of a confined space gas detector is to ensure the safety of personnel by identifying the presence of harmful gases before they reach dangerous levels.

Gas Detection

These devices can detect a variety of gases, including:

- Oxygen Levels: Monitoring for deficiency (which can cause asphyxiation) or enrichment (which increases fire risk).

- Toxic Gases: Such as carbon monoxide (CO) and hydrogen sulfide (H₂S), which can be lethal even at low concentrations.

- Flammable Gases: Like methane (CH₄), which pose explosion risks.

Real-Time Alerts

Equipped with sensors, the detector provides immediate alerts—audible, visual, or vibrational—when gas concentrations exceed safe thresholds.

Key Features

- Portability: Designed to be compact and lightweight, allowing workers to carry them easily into confined spaces for continuous monitoring.

- Multi-Gas Detection: Many models can simultaneously detect multiple gases, providing comprehensive safety coverage in environments where various gas hazards may be present.

- Durability: Built to withstand harsh conditions common in industrial settings, including resistance to water, dust, and impact.

- User-Friendly Interface: Clear displays and simple controls make it easy for users to interpret readings and respond quickly to potential hazards.

Importance in Confined Spaces

- Preventing Accidents: By detecting hazardous gases early, these devices help prevent incidents like explosions, fires, poisoning, and asphyxiation.

- Regulatory Compliance: Use of gas detectors is often mandated by safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA), to protect workers in confined spaces.

- Peace of Mind: Provides both workers and employers with confidence that the environment is being continuously monitored for safety risks.

How They Are Used

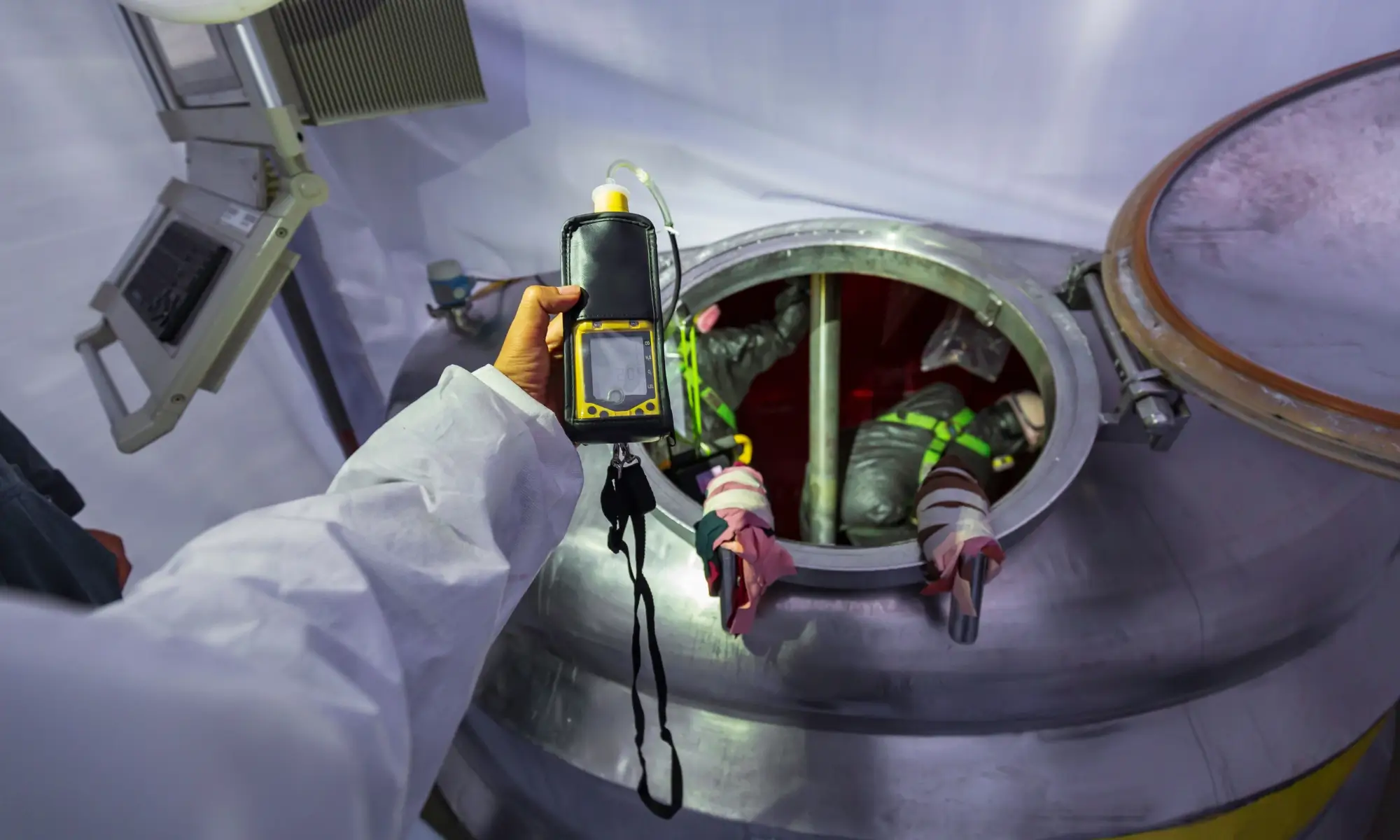

- Pre-Entry Testing: Before entering a confined space, workers use the detector to test the atmosphere from outside, ensuring it’s safe to enter.

- Continuous Monitoring: Once inside, the detector continues to monitor the air quality, alerting users to any changes in gas concentrations.

- Maintenance and Calibration: Regular calibration and maintenance are essential to ensure the detector provides accurate readings and functions properly.

Types of Confined Space Gas Detectors

Selecting the appropriate gas detector is crucial for ensuring safety in confined spaces. Different types of detectors are designed to meet specific needs based on the hazards present, operational requirements, and environmental conditions.

Single-Gas Detectors

- Purpose: Monitor one specific gas, such as oxygen, carbon monoxide (CO), or hydrogen sulfide (H₂S).

- Use Cases: Ideal when a particular hazardous gas is the primary concern in the confined space.

- Features:

- Compact and easy to use.

- Often wearable for continuous personal monitoring.

- Simple interface with clear readings.

Multi-Gas Detectors

- Purpose: Detect multiple gases simultaneously, typically up to four or five different gases.

- Use Cases: Suitable for environments where various gas hazards may be present, like oxygen deficiency, combustible gases, and toxic gases.

- Features:

- Customizable sensors to target specific gas combinations.

- Provide comprehensive monitoring in a single device.

- Equipped with alarms for each gas type.

Portable Gas Detectors

- Purpose: Handheld devices designed for mobility.

- Use Cases: Used by workers entering confined spaces to perform pre-entry testing and continuous monitoring.

- Features:

- Lightweight and battery-operated.

- Real-time readings with immediate hazard alerts.

- Durable construction for harsh environments.

Fixed Gas Detection Systems

- Purpose: Permanently installed detectors that provide continuous monitoring.

- Use Cases: Ideal for confined spaces accessed frequently or areas with constant gas hazards.

- Features:

- Integrated with facility control systems.

- Can trigger alarms, ventilation systems, or automatic shutdowns.

- Provide ongoing safety without the need for manual operation.

Wireless and Remote Monitoring Detectors

- Purpose: Use wireless technology to transmit gas readings to remote displays or control centers.

- Use Cases: Beneficial in situations where it’s unsafe for personnel to be present or for monitoring multiple confined spaces simultaneously.

- Features:

- Enable real-time remote monitoring.

- Improve response times during emergencies.

- Reduce the need for workers to enter hazardous areas.

Photoionization Detectors (PIDs)

- Purpose: Specialized detectors for volatile organic compounds (VOCs) and other low-level toxic gases.

- Use Cases: Used in industries like chemical manufacturing where exposure to VOCs is a concern.

- Features:

- High sensitivity to a wide range of organic compounds.

- Detects low concentrations that other detectors might miss.

- Essential for monitoring air quality and health hazards.

Understanding the various types of confined space gas detectors helps in making informed decisions to protect workers and maintain a safe working environment.

How Do Confined Space Gas Detectors Work?

Confined space gas detectors are vital tools designed to identify and measure hazardous gas concentrations in confined areas. They function by continuously sampling the air and using specialized sensors to detect the presence of dangerous gases.

Sensor Technologies

- Electrochemical Sensors: Detect specific toxic gases like carbon monoxide (CO) and hydrogen sulfide (H₂S). These sensors generate an electrical current proportional to the concentration of the target gas through a chemical reaction.

- Catalytic Bead Sensors: Identify combustible gases such as methane (CH₄). They work by oxidizing the gas on a heated bead, causing a temperature change that alters electrical resistance.

- Infrared (IR) Sensors: Measure gases that absorb infrared light, like carbon dioxide (CO₂). They detect the amount of IR light absorbed as it passes through the gas sample.

- Photoionization Detectors (PID): Detect volatile organic compounds (VOCs). They use ultraviolet light to ionize gas molecules, producing an electrical current proportional to the concentration.

Operation Process

- Air Sampling: The detector draws in air from the confined space, either passively or using a built-in pump.

- Gas Detection: The sampled air passes over the sensors, which react to specific gases present.

- Data Processing: The device interprets the sensor signals and calculates gas concentrations.

- Alerts: If gas levels exceed safe thresholds, the detector triggers alarms—audible, visual, or vibrational—to warn the user.

Key Features

- Real-Time Monitoring: Provides continuous readings to ensure immediate detection of hazards.

- Multi-Gas Detection: Many detectors can monitor several gases at once for comprehensive safety.

- Alarms and Notifications: Alert users promptly to dangerous conditions.

- Data Logging: Some models store readings for compliance reporting and analysis.

Calibration and Maintenance

- Regular Calibration: Ensures accuracy by adjusting the detector using known gas concentrations.

- Routine Checks: Includes sensor inspections and battery replacements to maintain reliability.

A proper understanding of how these detectors work enhances their effectiveness, ensuring that workers are protected from unseen gas hazards in confined spaces.

Selecting the Right Gas Detector

Choosing the appropriate gas detector is crucial for ensuring safety in confined spaces. The right detector effectively identifies potential hazards specific to the environment, helping to prevent accidents and comply with safety regulations.

Factors to Consider

- Types of Gases Present: Identify which hazardous gases are likely to be encountered. This determines whether you need a single-gas detector or a multi-gas detector capable of monitoring multiple gases simultaneously.

- Detection Capabilities: Ensure the detector can identify the specific gases of concern, such as oxygen levels, toxic gases like carbon monoxide (CO) or hydrogen sulfide (H₂S), and combustible gases like methane (CH₄).

- Environmental Conditions: Consider the working environment’s temperature, humidity, and pressure, as these can affect the detector’s performance. Choose a device designed to operate effectively under these conditions.

- Portability and Ease of Use: For confined space work, portable detectors are essential. Look for lightweight, user-friendly devices with clear displays and simple interfaces.

- Durability: Select detectors that are robust and built to withstand the work environment. Features like water and dust resistance, as well as impact protection, enhance longevity and reliability.

- Alarm Systems: The detector should have audible, visual, and vibrational alarms to alert users promptly when hazardous gas levels are detected.

- Battery Life: Opt for detectors with long battery life or rechargeable batteries to ensure continuous operation during work shifts.

- Maintenance and Calibration: Choose devices that are easy to maintain and require straightforward calibration procedures. Regular calibration is essential for accurate readings.

- Data Logging and Connectivity: Some detectors offer data logging for record-keeping and compliance reporting. Wireless connectivity can enable remote monitoring and data transfer.

Recommended Practices

- Conduct a Risk Assessment: Before selecting a detector, perform a thorough evaluation of the confined space to understand all potential gas hazards.

- Consult Regulations: Ensure the chosen detector meets industry standards and complies with regulations set by organizations like OSHA.

- Employee Training: Provide comprehensive training for workers on how to operate the detectors, interpret readings, and respond appropriately to alarms.

- Regular Maintenance: Implement a schedule for routine maintenance and calibration to keep the detectors functioning accurately.

- Trial and Evaluation: If possible, test different models to determine which detector best fits your specific needs and working conditions.

By carefully considering these factors, you can select a gas detector that not only fits the specific requirements of your confined space but also enhances overall safety and compliance.

Conclusion

Confined space gas detectors are vital for ensuring the safety of workers in hazardous environments. By understanding their functionality, selecting the appropriate device, and adhering to safety protocols, organizations can mitigate risks associated with confined spaces. Investing in reliable gas detection not only complies with regulatory standards but, more importantly, protects lives.